Powder Coating Services in Invercargill

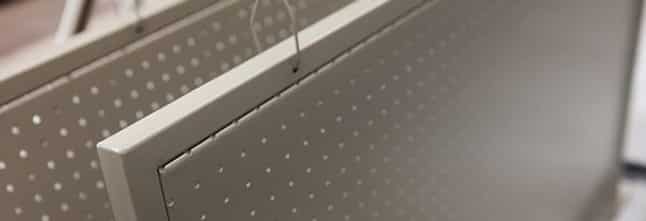

At Clive Wilson Powder Coating, located in the heart of Invercargill, we pride ourselves on delivering exceptional powder coating services. Our state-of-the-art facility and experienced team ensure high-quality, durable finishes for a wide range of applications.

Come in and see us today for more information

- Local Expertise: As Invercargill natives, we understand the specific needs and challenges of our community. We’re committed to providing personalized services that meet the unique demands of both individual and industrial clients in the region.

- Advanced Technology: Utilizing the latest in powder coating technology, we guarantee a superior finish that not only looks great but also withstands the test of time and the challenging New Zealand weather.

- Versatile Applications: From automotive parts to industrial machinery and decorative items, our powder coating solutions cater to a diverse array of needs, ensuring versatility without compromising on quality

Tailored Solutions for Every Need

Whether you’re looking for automotive powder coating in Invercargill or need specialized industrial solutions, our team is equipped to handle projects of all sizes. We offer a range of colors and finishes, tailored to your specific requirements.